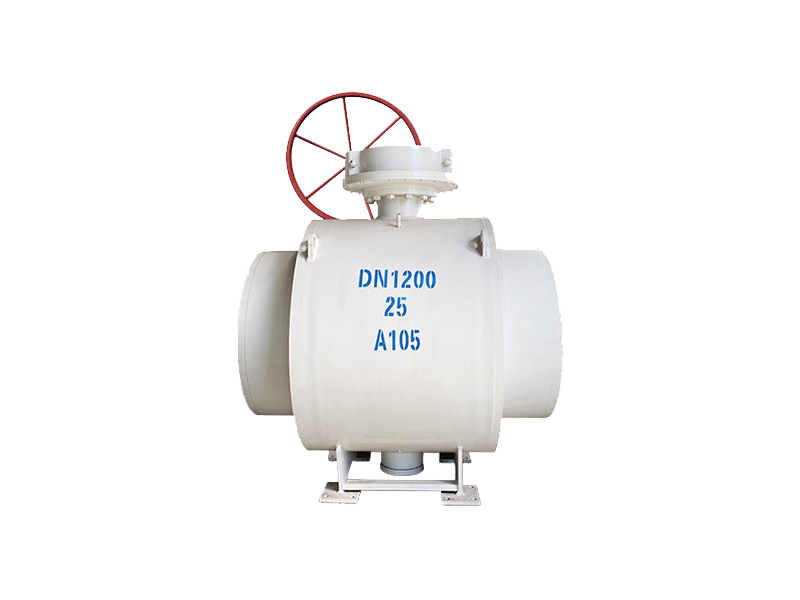

Spherical fixed full-welded ball valve

Spherical fixed full-welded ball valve

This series of fully welded ball valves are widely used in heating pipelines, city gas, municipal construction, and other industrial pipelines. Their main function is to cut off or connect the fluid passage in the pipeline. The closing member rotates 90° around the vertical center line of the valve body. Clockwise is to close, and counter-clockwise is to open.

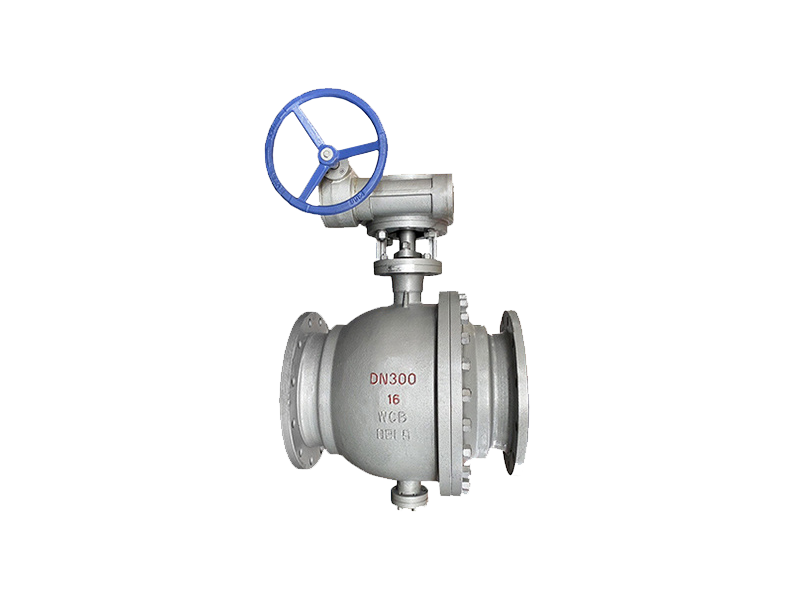

Cylindrical fixed full-welded ball valve

Cylindrical fixed full-welded ball valve

Floating Ball Structure: In a floating ball valve, the ball floats within the valve body. Under fluid pressure, the ball is tightly pressed against the outlet seat, creating a downstream seal. This structure is characterized by its simplicity and excellent sealing performance.

Fixed Ball Structure: In a fixed ball structure, the ball has an upper and lower rotating shaft. The lower part of the ball is embedded with a bearing, fixed by the lower stem, and the upper part is connected to the upper stem. The ball can only rotate along the vertical axis of the valve passage; it cannot move laterally like a floating ball valve. Therefore, when the fixed ball valve is in operation, the pressure of the upstream fluid and the spring force press the seat tightly against the ball, forming a reliable upstream seal. The fixed ball valve has a DBB function, meaning it can simultaneously shut off the medium upstream and downstream of the pipeline, providing safe and reliable valve sealing.

Fixed Ball Structure: In a fixed ball structure, the ball has an upper and lower rotating shaft. The lower part of the ball is embedded with a bearing, fixed by the lower stem, and the upper part is connected to the upper stem. The ball can only rotate along the vertical axis of the valve passage; it cannot move laterally like a floating ball valve. Therefore, when the fixed ball valve is in operation, the pressure of the upstream fluid and the spring force press the seat tightly against the ball, forming a reliable upstream seal. The fixed ball valve has a DBB function, meaning it can simultaneously shut off the medium upstream and downstream of the pipeline, providing safe and reliable valve sealing.

Cylindrical fixed full-welded ball valve

Cylindrical fixed full-welded ball valve

Fixed ball structure: The fixed ball structure has upper and lower rotating shafts. The lower part of the ball is embedded with bearings and fixed by the lower valve stem, while the upper part is connected to the upper valve stem. The ball can only rotate along the vertical axis of the valve passage and cannot move to one side like a floating ball valve. Therefore, when the fixed ball valve is working, the pressure of the fluid before the valve and the spring force push the valve seat to tightly press the ball, forming a reliable pre-valve seal. The fixed ball valve has a DBB function, which means that the valve can simultaneously cut off the medium upstream and downstream of the pipeline, and the valve sealing is safe and reliable.

Oval fixed welding ball valve

Oval fixed welding ball valve

Fixed ball structure: The fixed ball structure has upper and lower rotating shafts. The lower part of the ball is embedded with bearings and fixed by the lower valve stem, while the upper part is connected to the upper valve stem. The ball can only rotate along the vertical axis of the valve passage and cannot move to one side like a floating ball valve. Therefore, when the fixed ball valve is working, the pressure of the fluid before the valve and the spring force push the valve seat to tightly press the ball, forming a reliable pre-valve seal. The fixed ball valve has a DBB function, which means that the valve can simultaneously cut off the medium upstream and downstream of the pipeline, and the valve sealing is safe and reliable.

Hard-sealed ball valve

Hard-sealed ball valve

Main materials: carbon steel, austenitic stainless steel, duplex stainless steel, etc.;

Sealing surface hardening methods: supersonic spraying of tungsten carbide, chromium carbide, spray welding of nickel-based alloys, cladding of cobalt-based alloys, etc.;

Operating devices: handle, worm gear box, electric, pneumatic, hydraulic, pneumatic-hydraulic, electro-hydraulic.

Sealing surface hardening methods: supersonic spraying of tungsten carbide, chromium carbide, spray welding of nickel-based alloys, cladding of cobalt-based alloys, etc.;

Operating devices: handle, worm gear box, electric, pneumatic, hydraulic, pneumatic-hydraulic, electro-hydraulic.

Hard-sealed ball valve

Hard-sealed ball valve

Main materials: carbon steel, austenitic stainless steel, duplex stainless steel, etc.;

Sealing surface hardening methods: supersonic spraying of tungsten carbide, chromium carbide, spray welding of nickel-based alloys, cladding of cobalt-based alloys, etc.;

Operating devices: handle, worm gear box, electric, pneumatic, hydraulic, pneumatic-hydraulic, electro-hydraulic.

Sealing surface hardening methods: supersonic spraying of tungsten carbide, chromium carbide, spray welding of nickel-based alloys, cladding of cobalt-based alloys, etc.;

Operating devices: handle, worm gear box, electric, pneumatic, hydraulic, pneumatic-hydraulic, electro-hydraulic.