DN700

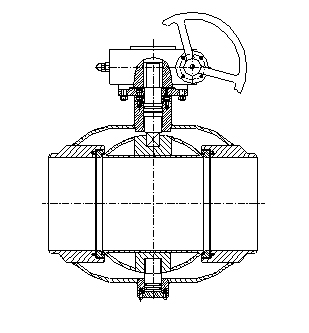

Oval fixed welding ball valve

Product Classification:

Key words:

Product Features

• Low flow resistance coefficient

The pressure loss of the ball valve at the nominal flow rate is the smallest among all valve types, equivalent to the flow resistance coefficient of a pipe of the same length, which is almost zero; our company's reduced-bore ball valve has undergone fluid analysis and theoretical calculation, and the flow path design maximizes the valve's flow capacity and reduces the flow resistance generated by the reduced-bore section.

• Double-direction sealing

The ball valve is not affected by the direction of the fluid medium; either end of the valve can be used as the upstream end, and the fixed ball valve can simultaneously cut off the fluid medium from both upstream and downstream.

• Good sealing performance

Double valve seat double-direction sealing, the valve seat seal is composed of VITONB+ suitable for different pressure levels of non-metallic polymers + hard seal, ensuring that the ball valve can achieve bubble-level sealing (i.e., zero leakage) under different pressure differences, and the sealing is safe and reliable.

• Long service life

The sealing surface of the non-metallic material has good lubricity, and the friction and wear with the sphere are small. The structure is a multi-stage seal, and the action of the spring pre-tightening force makes the sealing safe and reliable, thereby improving the service life of the ball valve.

Product Installation

1. The pipes connected to the valve should be cleaned to avoid iron filings, sand, welding slag, and other debris from damaging the valve sealing surface.

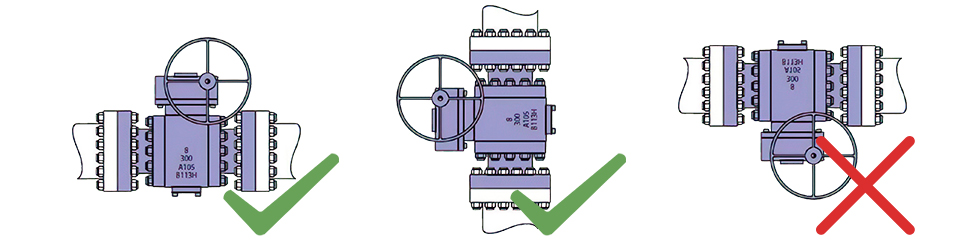

2. This series of ball valves can be installed in any position, and either end of the valve can be used as the upstream end. Both horizontal and vertical installation of the valve are possible, but the valve is prohibited from being installed upside down to prevent corrosion of the valve stem;

3. During installation, the valve should be kept fully open (adjusted in place at the factory), otherwise it may cause damage to the valve; Warning: Do not leave the valve in a half-open or half-closed state.

4. The valve center should be aligned with the pipe center and pipeline before welding installation:

5. Welding connections should be constructed according to welding procedures that have passed welding procedure qualification, and during installation welding, prevent welding slag and weld beads from entering the valve cavity and damaging the sealing surface. During installation, the valve should be in the fully open position; otherwise, it may cause damage to the valve. Warning: For butt-welded ball valves, do not install while the valve is closed. If the valve must remain closed, apply grease to the exposed surface of the sphere to protect it from damage by splashing welding slag.

6. During preheating, welding, and stress relief, the temperature at any point on the valve body 75mm away from the weld seam cannot exceed 200℃. Please use a thermometer to check the temperature.

7. During the valve installation process, the cleanliness of the valve body cavity should be ensured to prevent debris from entering the cavity;

8. After welding and installation of the welding end valves, visual inspection or non-destructive inspection should be carried out to confirm that there are no cracks, weld beads, undercuts, and other harmful defects. Non-destructive testing of welds should be performed as required:

9. For valves with actuators, the electrical, pneumatic, and hydraulic lines should be connected according to the wiring diagram or piping diagram in the instructions. Before connection, confirm the correctness of the lines; the open and closed positions of the valve have been adjusted in place at the factory and do not need to be readjusted.

10. The actuators of buried pipeline valves cannot be immersed in water or mud to avoid damage to the actuators;

Note: If the valve is inevitably immersed in water or mud for a long time, please inform the manufacturer in advance so that the manufacturer can take countermeasures in advance.

11. When installing large-diameter welded ball valves, the weight of the valve cannot be entirely applied to the pipeline, and fixed piers or supports should be set up for support.

12. Valves with external insulation requirements should have the protective layer constructed before the medium is introduced. Set up fixed piers or brackets for support.

12. Valves with external insulation requirements should have the protective layer constructed before the medium is introduced.

Design Parameters

Design and Manufacturing: GB/T12237、GB/T37827、GB/T12224、ASME B16.34

Inspection and Testing: GB/T13927、JB/T9092、I5O 5208

Fire Test: GB/T26479、APl 6FA、API607

Pressure Level: 1.6Mpa~4.0Mpa;

Nominal Diameter Range: DN15~1400mm;

Applicable Medium: Water, gas, oil, etc;

Applicable Temperature: -29℃~200℃.

Main Component Material Details

| Part Name | Standard Material | Stainless Steel Material | Forging Material |

| Valve Body | 20# | 304 | A105 |

| Valve Cover | 20# | 304 | A105 |

| Ball | 304 | F304 | F304 |

| Valve Seat | A105+ENP | 304 | A105+ENP |

| Valve Seat Seal Ring | RPTFE | RPTFE | RPTFE |

| Valve Stem | 20CR13 | 304SS | 20CR13 |

| Packing Gland | 20# | 304 | A105 |

| Spring | INCONEL X-750 | INCONELX-750 | INCONEL X-750 |

| Pivot | 20CR13 | 304SS | 20CR13 |

| Upper and Lower Diameter | 20# | 304 | A105 |

| Sliding Bearing | 304+MOS2+PTFE | 304+MOS2+PTFE | 304+MOS2+PTFE |

| O-ring | Fluororubber | Fluororubber | Fluororubber |

| Anti-static Device | 304SS | 304SS | 304SS |

Troubleshooting

Malfunction | Cause of Failure | Troubleshooting Methods |

Operational Jamming | 1. Drive unit damage 2. Tilted packing gland installation 3. Valve seat area blockage 4. Bent and seized stem | 1. Maintain and repair the drive unit 2. Loosen the packing gland screws and reinstall the packing gland correctly 3. Turn the handwheel and operate the valve several times with small movements 4. Rectify or replace the stem (please contact our company) |

Valve Seat Leakage | 1. Valve not fully closed 2. Incorrect setting of the drive unit limit switch 3. Sealing surface damaged due to abrasion | 1. Operate the valve to the fully closed position 2. Adjust the drive unit limit switch appropriately 3. Please contact our company for repair |

Stem Leakage | 1. Stem seal damaged 2. Stem damaged | 1. Replace the stem packing 2. Repair or replace the stem (please contact our company) |

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

Recommend Products

At present, it can produce more than a dozen series of more than 1,000 specifications of safety valves, power station valves, extraction check valves, gate valves, ball valves, check valves, butterfly valves, drain valves, balance valves, and regulating valves of different types and specifications.