DN300

Hard-sealed ball valve

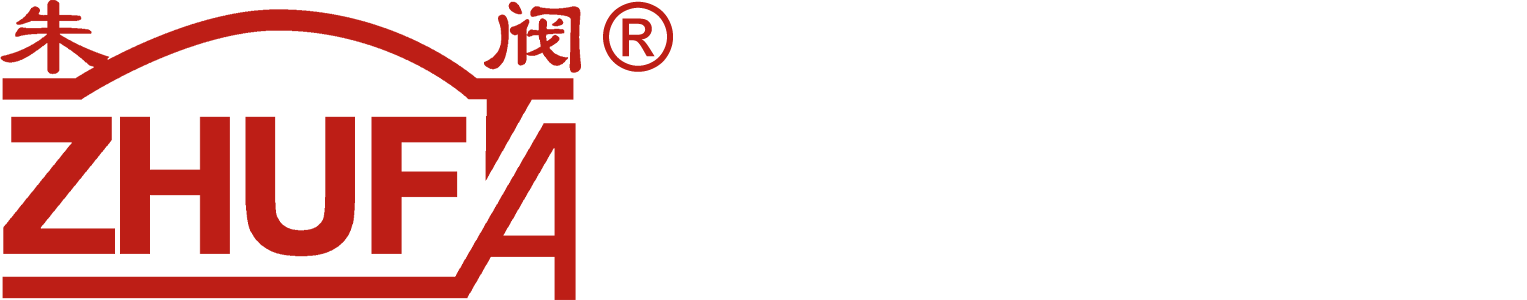

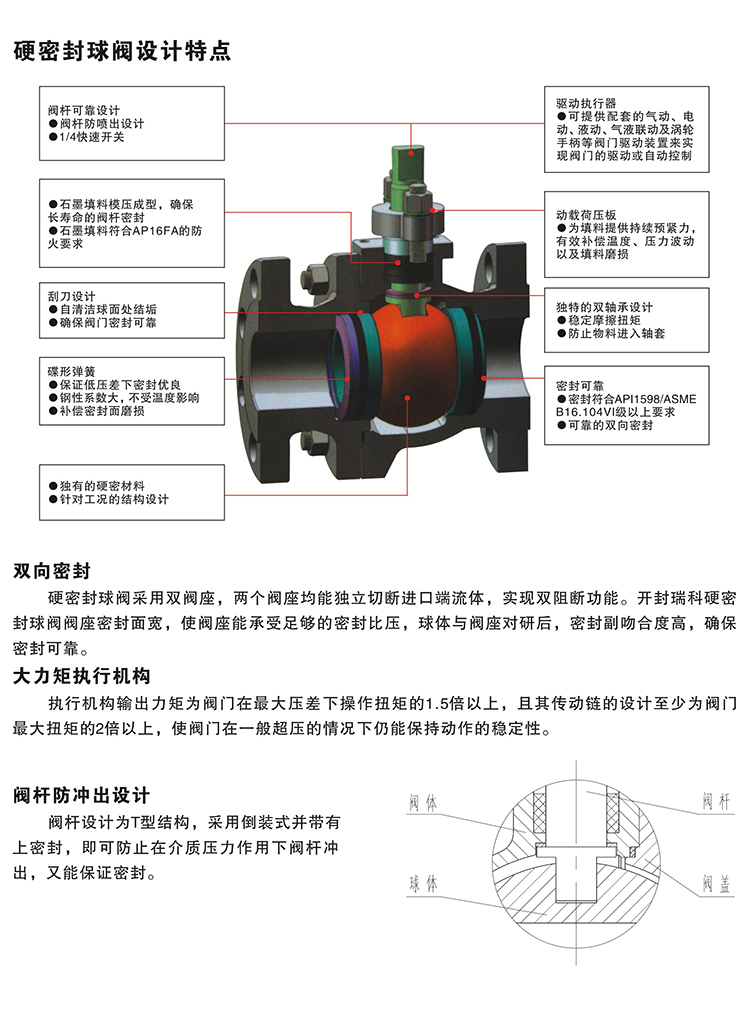

Sealing surface hardening methods: supersonic spraying of tungsten carbide, chromium carbide, spray welding of nickel-based alloys, cladding of cobalt-based alloys, etc.;

Operating devices: handle, worm gear box, electric, pneumatic, hydraulic, pneumatic-hydraulic, electro-hydraulic.

Product Classification:

Key words:

Technical Parameters of Hard Seal Ball Valves

Design Standards: API6D, API608, GB/T21385, etc.;

Inspection Standards: API598, ASME B16.104, JB/T9092;

Flange Connection: ASME B16.5, HG, GB, etc.;

Structural Length: ASME B16.10, GB/T12221, etc.;

Pressure Rating: 150Lb~2500Lb(1.6MPa~42.0MPa);

Nominal Diameter Range: NPS1/2~24(DN15~DN600);

Applicable Temperature: -29℃~540℃;

Main Body Material: Carbon steel, Austenitic stainless steel, Duplex stainless steel, etc.;

Sealing Surface Hardening Method: Ultrasonic spraying of tungsten carbide, chromium carbide, nickel-based alloy spraying, cobalt-based alloy cladding, etc.;

Operating Device: Handwheel, worm gear box, electric, pneumatic, hydraulic, pneumatic-hydraulic, electro-hydraulic.

Coating Material

The coating material must be wear-resistant, corrosion-resistant, erosion-resistant, have high binding force, low porosity and low friction coefficient. The properties of different base materials must also be considered.

Serial Number | Spraying Material | Coating Hardness | Coating Thickness | Spraying Method | Operating Temperature | Base Material |

1 | Cr-Ni-Si-B | 57-63(HRC) | 400-600um | Thermal Spraying | <650°C | SS、F51 |

2 | Cr-Ni-WC-Co | 60-65(HRC) | 400-600um | Thermal Spraying | <650°C | SS、F51 |

3 | W-C-Co | 68-74(HRC) | 150-250um | Ultrasonic Spraying | <450°C | Cr13、SS、F51 |

4 | W-C-Co-Cr | 68-72(HRC) | 150-250um | Ultrasonic Spraying | <470°C | Cr13、SS、F51 |

5 | Cr-C-Ni-Cr | 53-57(HRC) | 150-250um | Ultrasonic Spraying | <850°C | Cr13、SS、F51 |

6 | W-Cr-Co-N | 50-55(HRC) | 150-250um | Ultrasonic Spraying | <650°C | Cr13、SS、F51 |

After hardening treatment of the sealing surface, wear resistance, erosion resistance and corrosion resistance can be obtained. Various hardening treatment methods can be selected according to different working conditions.

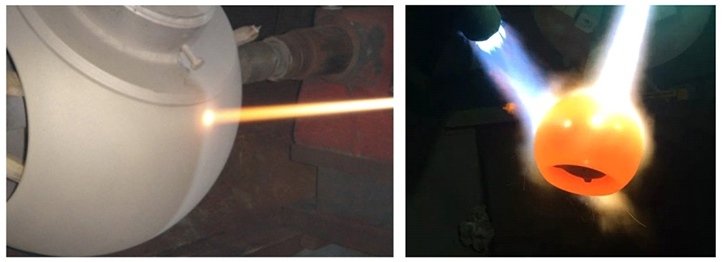

• HVOF supersonic spraying: Supersonic flame powder spraying of tungsten carbide and chromium carbide, etc. The hardened coating has low porosity, a binding force greater than 70 MPa, a hardness of up to HRC80, and a hardened layer thickness of 150~250 μm.

• High-temperature spraying: Oxyacetylene flame spraying of alloy powder. The sprayed layer is once spray-melted or the sprayed layer is secondary re-melted using a combustion flame, so that the sprayed layer and the base material are in a metallurgical bonding state. The binding force can reach 400 MPa, the hardness can reach HRC65, and the hardened layer thickness is 400~600 μm, and can reach 1.5 mm thick.

• Cladding: The sealing surface is clad with a cobalt-based alloy, with a hardness of up to HRC44, and a cladding layer thickness ≥2mm.

• Whole sintered tungsten carbide: The sealing element is made of alloy powder sintered at high temperature and ground. It has low porosity, a hardness of up to HRA90, and high hardness and wear resistance.

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

Recommend Products

At present, it can produce more than a dozen series of more than 1,000 specifications of safety valves, power station valves, extraction check valves, gate valves, ball valves, check valves, butterfly valves, drain valves, balance valves, and regulating valves of different types and specifications.