DN500

Double-seated metal hard seal butterfly valve

Product Classification:

Key words:

Overview

This series of fully welded ball valves are widely used in heating pipelines, city gas, municipal construction, and other industrial pipelines. Their main function is to cut off or connect the fluid channel in the pipeline. The closing member rotates 90° around the vertical centerline of the valve body; clockwise to close, counter-clockwise to open.

Structural Features

1. The valve body is welded from two hemispherical forgings, using a single-weld seam method. The weld seam is located in the middle of the valve body, away from the sealing element.

2. The valve body structure is compact, with greater rigidity, ensuring that the valve remains flexible and free of jamming even under axial pressure, tensile force, and radial bending moments. The valve also maintains a good seal.

3. The valve seat is embedded with soft material polymer sealing rings (such as polytetrafluoroethylene) suitable for different pressure levels, and a fluororubber triangle ring. This creates a triple seal with the metal hard seal, making the valve seal safer and more reliable.

4. The elastic sealing valve seat achieves dynamic compensation, solving the problem of excessive frictional torque caused by thermal expansion.

5. The valve seat has a self-cleaning function.

6. The ball surface is chemically nickel-phosphorus plated, and after heat treatment, the hardness reaches HRC>60, improving the ball's anti-bite performance and sealing.

Technical Parameters

Design and Manufacturing: GB/T12237、GB/T37827、GB/T12224

Inspection and Testing: GB/T13927、GB/T26480、ISO 5208

Pressure Level: 1.6Mpa~4.0Mpa;

Nominal Diameter Range: DN500~1400mm;

Applicable Medium: Water, gas, oil, etc.;

Applicable Temperature: -29℃~200℃.

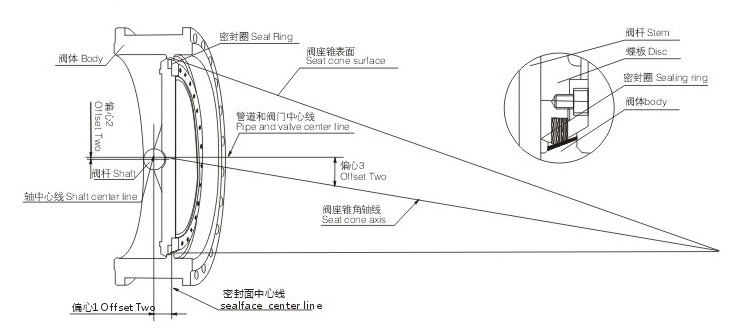

Three-Eccentric Geometry Diagram

1. One eccentric axis deviates from the sealing surface center line

2. The second eccentric axis deviates from the pipeline and valve center line

3. The unique eccentric valve seat bevel angle and the angle with the pipeline center. This ensures that the valve seat and sealing ring are completely separated during the entire opening and closing process of the valve. This structure utilizes the cam effect and completely eliminates friction, eliminating the possibility of wear and leakage.

Main Technical Parameters

| Nominal Diameter | DN(mm) | 50~1600 | 50~500 | |||

| Nominal Pressure | PN(MPa) | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 |

| Test Pressure | Strength Test | 0.9 | 1.5 | 2.4 | 3.75 | 6.0 |

| Sealing Test | 0.66 | 1.1 | 1.76 | 2.75 | 4.4 | |

| Leakage Rate | <0.1×DNmm/s (Complies with GB/T13927-92 standard) | |||||

| Applicable Temperature | Carbon Steel: -29℃~350℃ Stainless Steel: -40℃~600℃ | |||||

| Applicable Medium | Dust, air, water, steam, coal gas, oil, and corrosive media such as acids, alkalis, and salts. | |||||

| Drive Type | Worm gear drive, pneumatic drive, electric drive. | |||||

Material of Main Parts

Part Name | Material |

Valve Body | Welded steel, cast steel, stainless steel, alloy steel |

Disc | Welded steel, cast steel, alloy steel, stainless steel |

Body, Plate, Sealing Ring | Stainless steel combined with high-temperature asbestos board in multiple layers |

Stem | 2Cr13, 1Cr13 stainless steel, chromium molybdenum steel |

Bearing | Aluminum bronze, austenitic stainless steel, 304 nitriding |

Packing | Flexible graphite |

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

Recommend Products

At present, it can produce more than a dozen series of more than 1,000 specifications of safety valves, power station valves, extraction check valves, gate valves, ball valves, check valves, butterfly valves, drain valves, balance valves, and regulating valves of different types and specifications.